As a leading name in gasket manufacturing for over 37 years, Conic Auto has witnessed—and driven—remarkable changes in the industry. Today, the gasket sector is undergoing a transformation, powered by technological innovation, sustainability, and evolving customer needs. Here’s a look at the latest trends shaping the future of gasket manufacturing and how Conic Auto is staying ahead of the curve.

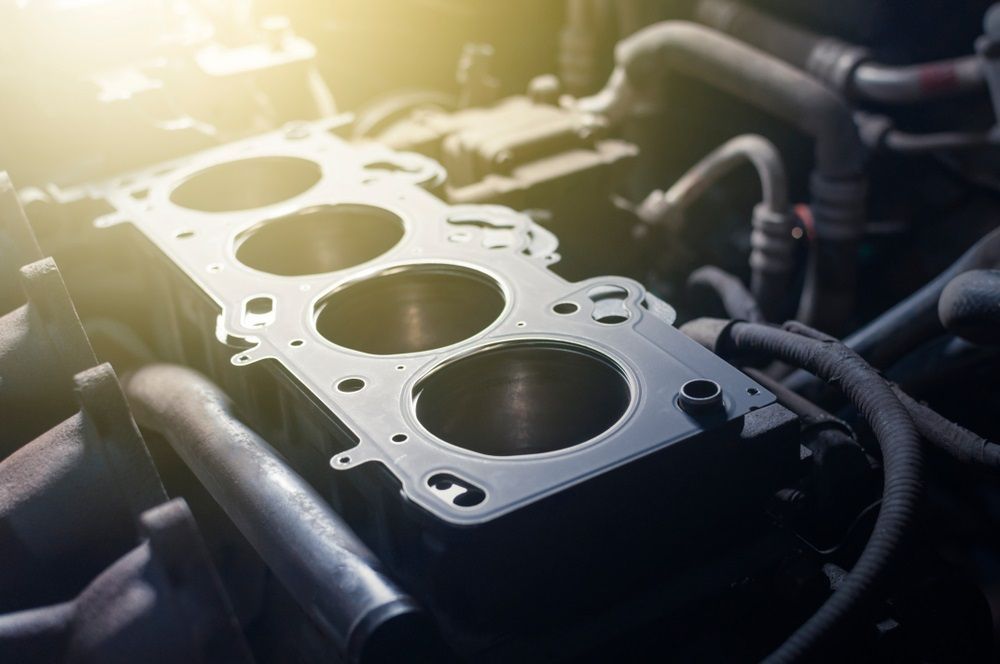

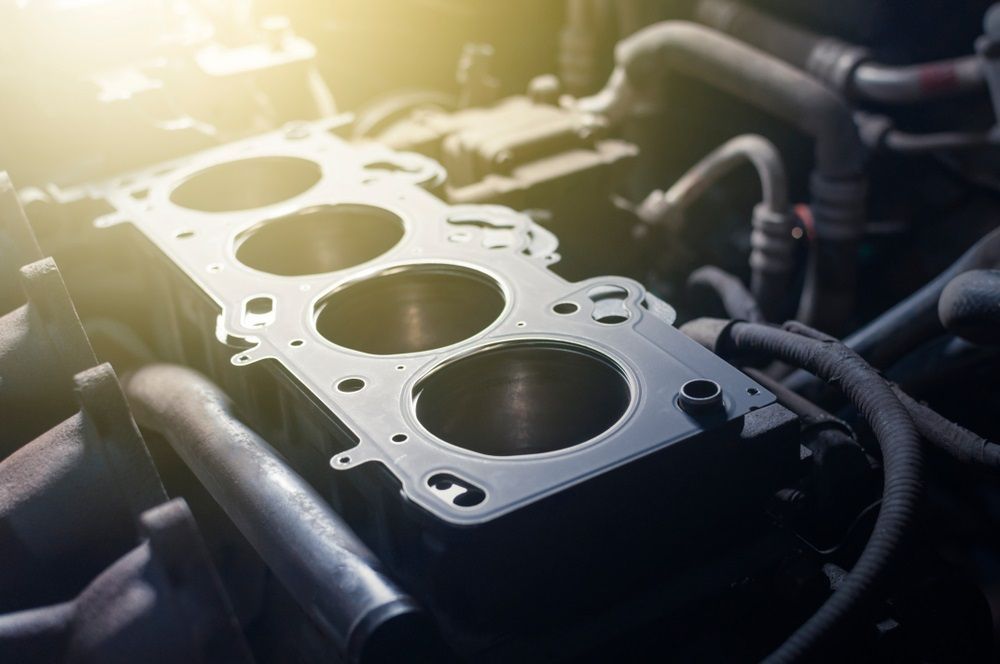

1. Advanced Materials for Enhanced Performance

Modern gasket applications demand materials that can withstand higher temperatures, pressures, and aggressive chemicals. The shift from traditional asbestos to advanced non-asbestos composites, PTFE, graphite, and elastomers is now the industry norm. These materials offer superior sealing, longevity, and safety, meeting the needs of automotive, oil & gas, and industrial customers alike.

2. Sustainability and Eco-Friendly Manufacturing

Environmental responsibility is no longer optional. Manufacturers are investing in eco-friendly materials and greener production processes. At Conic Auto, we’re committed to reducing our environmental footprint by adopting sustainable raw materials, energy-efficient manufacturing, and recycling initiatives—aligning with global regulatory demands and customer expectations.

3. Digital Transformation and Smart Manufacturing

The integration of digital technologies—such as automation, IoT, and AI-driven quality control—is revolutionizing gasket production. These innovations enable real-time monitoring, predictive maintenance, and improved traceability, resulting in higher product consistency and reduced lead times. Conic Auto’s state-of-the-art facility leverages automation and precision machinery to deliver consistent quality at scale.

4. Customization and Rapid Prototyping

With industries demanding tailored solutions, the ability to design and manufacture custom gaskets quickly is a key differentiator. Advances in CAD/CAM software, rapid prototyping, and flexible manufacturing lines allow Conic Auto to meet unique customer requirements efficiently, whether for automotive, aerospace, or specialized industrial applications.

5. High-Performance and Long-Life Solutions

Customers are seeking gaskets that offer not just superior sealing but also extended service intervals and lower maintenance costs. Innovations in multi-layer, edge-moulded, and heat shield gaskets are enabling better performance, especially in demanding environments like high-performance engines and critical industrial systems.

6. Market Growth Driven by New Sectors

The rise of electric vehicles (EVs), renewable energy, and stricter emission standards are fueling demand for new gasket technologies. Specialized gaskets for battery packs, thermal management, and electrical insulation are becoming increasingly important, opening new growth avenues for manufacturers like Conic Auto.

Conclusion

The gasket manufacturing industry is evolving rapidly, with advanced materials, sustainability, digitalization, and customization leading the way. At Conic Auto, we are proud to be at the forefront of these trends, delivering innovative, high-quality sealing solutions that power the world’s most demanding industries.

Stay tuned for more updates as we continue to shape the future of gasket technology—precision gaskets, engineered to perform.